Modification of shellac varnish by nanoparticles and a perfluoropolyether based polymer

Keywords:

Shellac, Wood, Inorganic nanoparticles, PerfluoropolyetherAbstract

Shellac has been widely used as a protective material for wooden furniture and musical instruments, due to its remarkable properties such as ease of application, high adhesion to the wood surface and protective properties along with its nonpoisonous nature. However, shellac varnishes have also some limitations such as softness of the coating, photodegradation, and sensitivity to alcoholic solvents and to pH variations. In the present study, de-waxed natural shellac (food quality shellac from Kremer-Pigmente) was selected and modified by introducing different inorganic nanoparticles as well as a fluorinated polymer. Silicates nanoparticles were added with the aim of improving the film hardness, while ZnO nanoparticles were expected to reduce photodegradation of the shellac matrix and finally, fluorinated polymer was considered with the aim of increasing chemical resistance and water repellent character of the resulting material. Four different shellac materials were prepared for these purposes by dispersing nanoparticles (silica, montmorillonite, zinc oxide) and perfluoropolyether in alcoholic solutions of shellac. Different experimental analyses were performed on both modified shellac films and maple wood specimens treated by brushing. Characteristics of modified shellac materials were investigated by performing hardness test, contact angle measurements, evaluation of chromatic variation after UV ageing, solubility and alkali resistance tests. SEM-EDS analyses were also carried out on films and treated wood specimens.

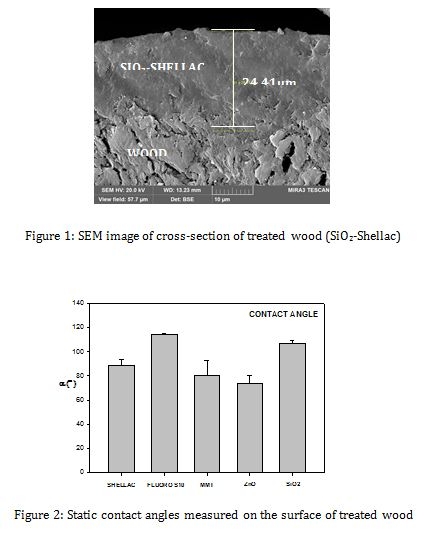

Quality and thickness of the coating are important parameters when products are developed for real case applications. Both native shellac and modified shellac treatments on wood specimens provided good quality coatings whose thickness was very close to real applications (about 25 µm, see Figure 1). Hardness measurements performed by international standard test indicated that the presence of silica or montmorillonite nanoparticles in shellac improves the hardness of the resulting coating. In addition, SiO2-shellac applied on wood specimens afforded an improvement of hydrophobic properties (see Figure 2), while Montmorillonite-shellac increased the base resistance property with respect to the native shellac. ZnO-shellac treatment preserved almost unaltered the chromatic properties (L*, a* and b* coordinates of the CIELAB space) with respect to native shellac, even after UV ageing (750 h). Shellac modified by perfluoropolyether showed an improvement of hydrophobic behaviour and photo-stability after artificial ageing.

Acknowledgement: The authors would like to acknowledge Dr. Claudio Canevari (Civica Scuola di Liuteria, Milan, Italy) for supplying different shellac batches, wood samples and also kind guidance for the research work.