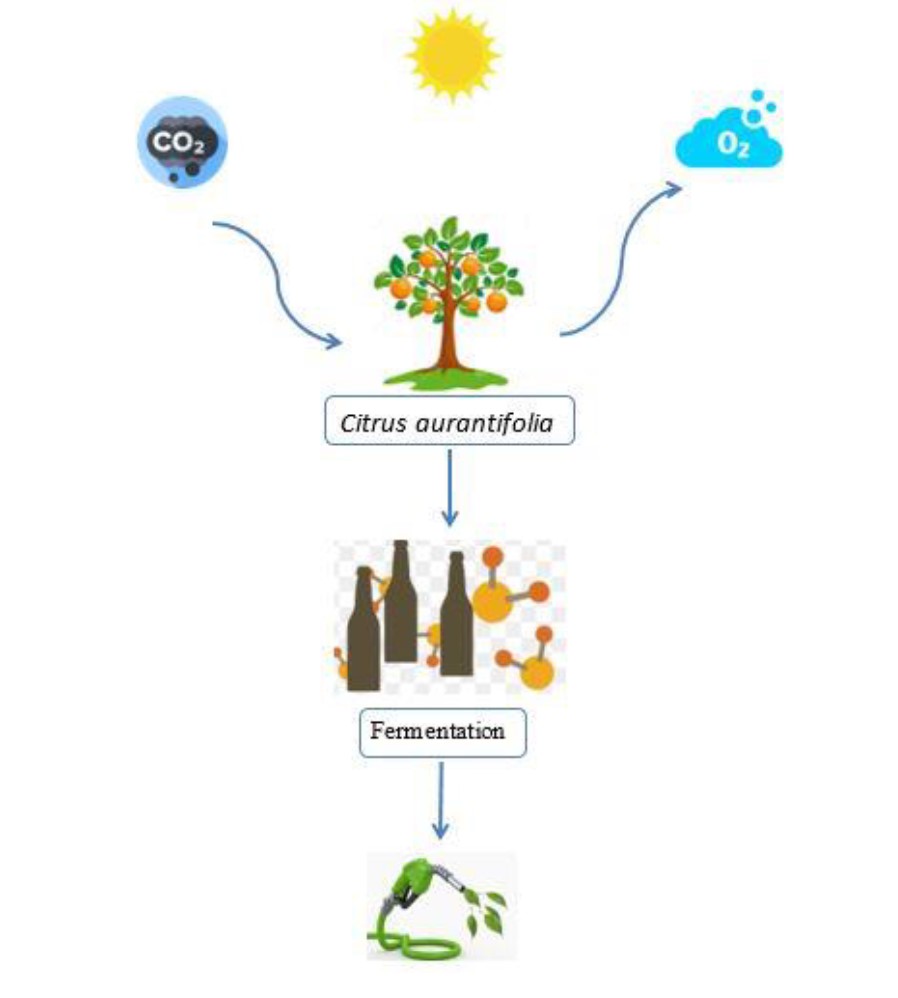

Optimization of Fermentation for Bioethanol Production from sour Citrus aurantifolia Fruit Juice using Natural Palmyrah Toddy Yeast

DOI:

https://doi.org/10.31357/vjs.v26i01.6415Abstract

Large scale consumption of fossil fuel to meet the increasing demand causes adverse effects on the environment due to the emission of harmful greenhouse gases. The production of bioethanol from diverse fruit juices that are underutilized because of poor taste quality could be one of the alternative fuels to overcome the issues. The objective of the study was to produce bioethanol from sour Citrus aurantifolia fruit juice using palmyrah toddy yeast and to optimize the conditions to increase the bioethanol yield. The sour Citrus fruit juice was inoculated with palmyrah toddy yeast (Saccharomyces cerevisiae - 2g/L) in the fermentation media (100ml, sour Citrus fruit juice: distilled water = 1:3) composed of 10 g/L yeast extract, 10 g/L KH2PO4, 2 g/L (NH4)2SO4, 2 g/L peptone and 0.5 g/L MgSO4·7H2O and allowed for fermentation for 24 hours at room temperature. The amount of ethanol produced from the Citrus juice was 0.8% (V/V) after 24 hours of fermentation. In order to optimize the fermentation process for Citrus aurantifolia, a variety of experimental parameters were studied, including the type of nitrogen source (ammonium sulphate, ammonium nitrate, ammonium chloride, and urea), inoculum size (0.4 to 1.0 g/100 mL), temperature (20 to 40 °C), rotation speed (50 to 250 rpm), concentration of raw fruit juice (5 to 100%), amount of urea (0.1 to 2.0 g/100 mL), carbon source (glucose, sucrose, maltose, and dextrose), amount of sucrose (1 to 20 g), pH of the medium (3.0 to 8.0), and incubation period (24 to 96 h). After conducting the experiments, it was found that using Citrus aurantifolia at 100% concentration resulted in significantly higher ethanol yields of 11.50%, which was 14.37 times higher than the non-optimized conditions. The highest yield was achieved when the fermentation was carried out at 35 °C for 24 h with an inoculum concentration of 0.5 g/100 mL, a rotation speed of 150 rpm, a pH of 4.0, 0.1 g/100 mL urea as the nitrogen source, and 10 g/100 mL sucrose as the carbon source. Large scale fermentation study using bioreactor should be done to determine whether this finding could be commercialized.

Key words: Bioethanol, Fermentation, Palmyrah toddy yeast, Citrus fruit juice, Urea